Exploration and Mining

Our mining operations focus on extracting copper, antimony, and other valuable minerals using modern techniques with minimal environmental impact. Our exploration team continually assesses new reserves using advanced geological surveying methods.

Grinding Mill

Grinding Mill at mine site; for a polymetallic mine processing Cu, Sb, and Pb ores, a closed-circuit ball mill with hydro cyclones offers the best balance of flexibility and efficiency. Prioritize: 1. Rubber/composite liners for corrosion resistance. 2. VFD drives to adjust speed for ore variability. 3. Advanced dust capture for toxic metals. Always conduct ore-specific grindability tests (Bond, SPI) before final mill selection.

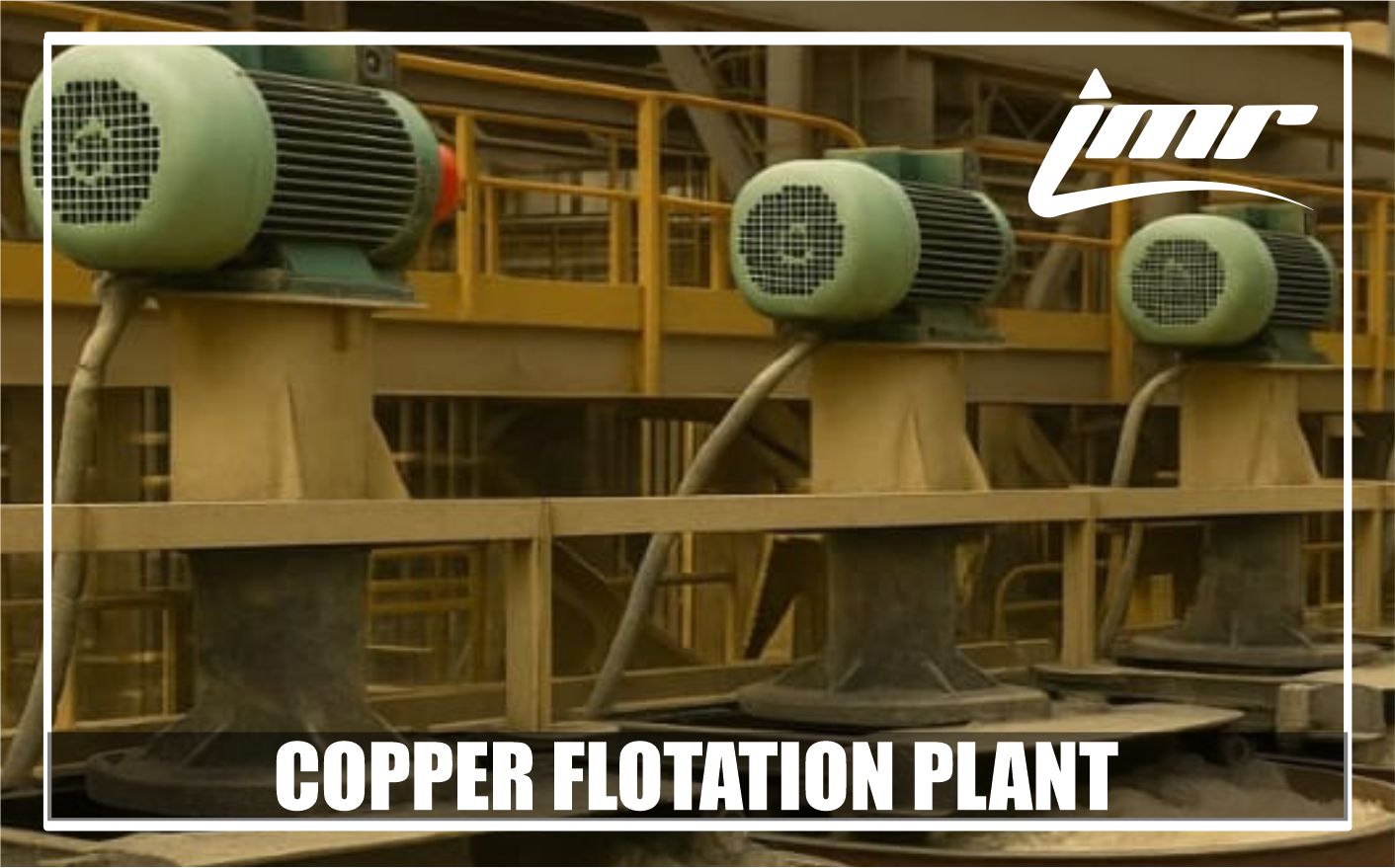

Copper Flotation Plant

Our state-of-the-art flotation plant utilizes advanced technology to separate valuable minerals from ore. With a capacity of 1,000 tons per day, we achieve industry-leading recovery rates while maintaining strict environmental controls.

Copper Smelting Plant

After getting copper concentrate from Copper Flotation plant smelting of concentrate into Furnace and then electrolysis makes 99.995% pure copper ingots.

Antimony Roasting Plant

An Antimony Roasting Plant is a facility dedicated to thermally oxidizing antimony sulfide(sibnite) concentrates. Its primary goals are to remove sulfur, volatilize and separate antimony as an oxide (either for direct sale or as feed for metal production), and manage impurities and emissions through sophisticated gas cleaning and environmental control systems. It’s a critical step in the primary production pathway for antimony metal and trioxide.

Lead Smelting Plant

Lead Smelting Plant is an industrial facility designed to extract metallic lead (Pb) from lead-bearing ores (primarily galena, PbS) through pyrometallurgical processes. Its core function is to reduce lead compounds into molten lead bullion while separating impurities into slag or off-gas streams.

Gold Refinery

Small-Scale Mine Gold Refinery: An on-site processing unit designed to extract and refine gold from copper-gold ores (15–18 g Au/ton) using compact, low-capacity methods. It bypasses centralized refineries, enabling direct dore bar production at the mine while minimizing transport costs and security risks.

Laboratory

Small laboratory at a mine site, optimized for rapid decision-making, process control, and gold/copper ore analysis. Core Purpose of a Mine-Site Lab including Rapid grade verification (ore control, stockpile management), Process monitoring (tailings assays, recovery calculations), Metallurgical testing (optimizing crushing/grinding/leaching) and Environmental compliance (effluent testing). Why On-Site Labs Pay Off: Cut assay turnaround from 5 days (off-site lab) to 8 hours and to Reduce processing of sub-grade ore (saves $100s/ton).

Run-of-the-River (RoR) Micro Hydro Plant

Small-scale hydropower system (typically 5kW–1MW capacity) that generates electricity by harnessing the natural flow and elevation drop (head) of a river without large dams or reservoirs. Water is diverted through a turbine and returned to the river downstream, minimizing environmental disruption. Efficiency: Modern turbines: 75–90%, System losses (penstock friction, silt): 10–25%. Advantages for Remote Mines, 24/7 Power: Uninterrupted operation vs. diesel generators, Low OpEx: No fuel costs; minimal maintenance, Resilience: Withstands extreme weather if designed properly, Eco-Friendly: Zero emissions; preserves river.

Community Services

We are committed to uplifting local communities through essential services, including a Masjid and a fully integrated technical school. The school offers education from primary to secondary levels, with a strong focus on vocational training in mining, plant operations, and related technical fields—empowering the next generation with practical skills and sustainable career opportunities.